AI in Manufacturing Part (2) : Creating Control Plan with AI

Learn how to create an AIAG-aligned Manufacturing Control Plan using AI. Step-by-step guide with PFMEA linkage, prompts, and real machining examples.

Thank you for the overwhelming 1,000+ views of the previous blog on creating FMEA through AI.

This article is a continuation of the previous article written by Srinivas TV on -Creating FMEA with AI

In this post, he will share how to create a Control Plan, the second most important document in manufacturing - the second aspect of the “Golden Thread”.

If you haven’t read the previous article on FMEA yet, check out the article here:

No Time to Read? Here’s the Scoop

A Control Plan translates your PFMEA into shop-floor execution

It defines what to control, how to control, how often, and what to do when things go wrong

A good Control Plan must be directly traceable to PFMEA failure modes

AI can generate an AIAG-aligned Control Plan in minutes—if the prompt is structured correctly

Uploading PFMEA + drawing works, but prompt quality determines consistency

Structured prompts ensure repeatability, audit readiness, and engineering intent

Control Plan: The document responsible for Process Quality

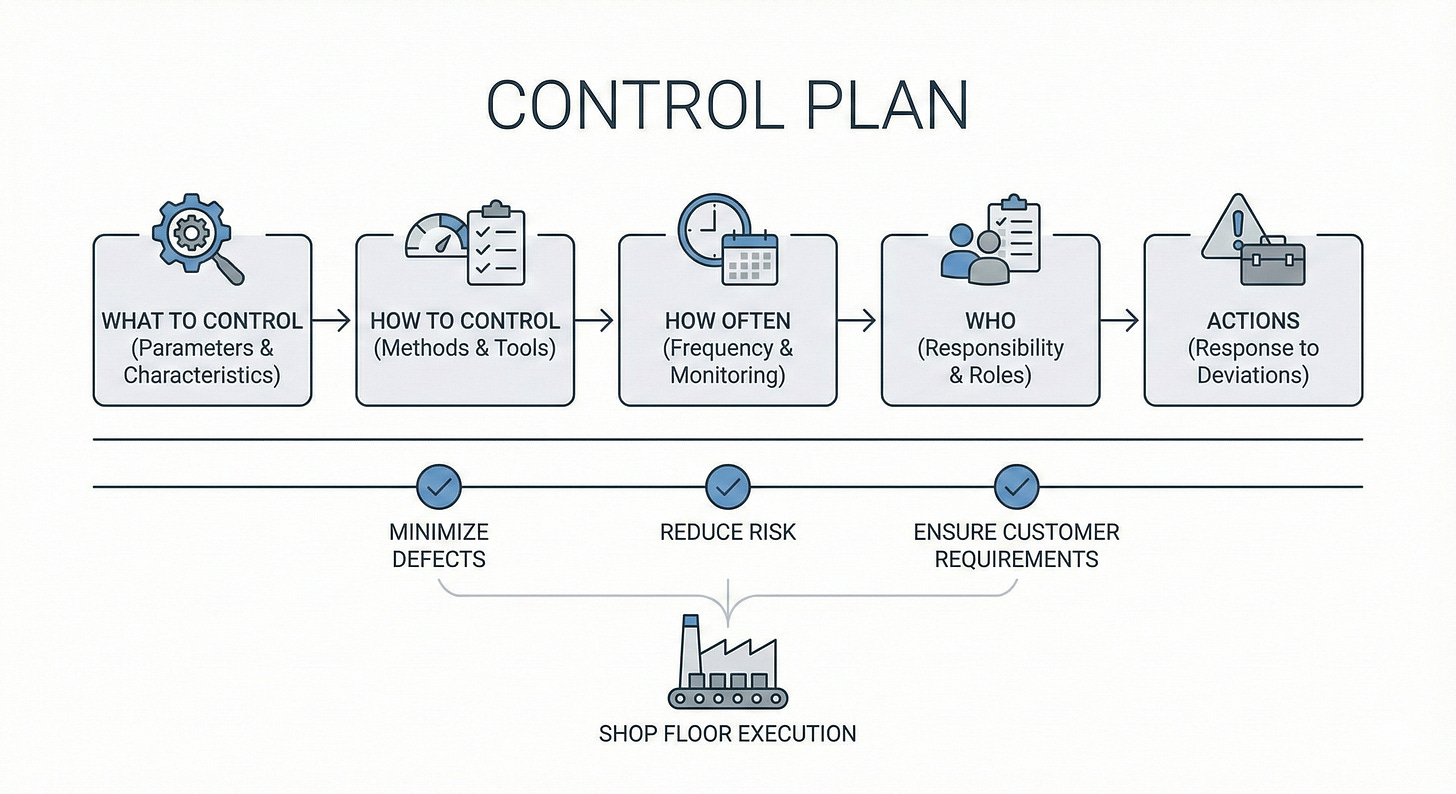

A Control Plan is a structured document used in Lean Six Sigma and Quality Management to ensure that critical process parameters and product characteristics are consistently maintained within defined limits.

The Control Plan clearly defines what to control, how to control it, how often to monitor, who is responsible, and what actions to take if deviations occur. By proactively identifying potential variations and standardizing responses, it helps minimize defects, reduces risk, and ensures customer requirements are continuously met on the shop floor.

In simple terms, a Control Plan acts as a quality assurance checklist that keeps a process stable, predictable, and capable over time.

A Control Plan derives its inputs from the FMEA (Failure Modes and Effects Analysis). The current control column of the FMEA gets translated into a complete Control Plan document.

Ideally, it needs to be prepared by Process Engineers and signed off by the Production Department and the Quality Department.

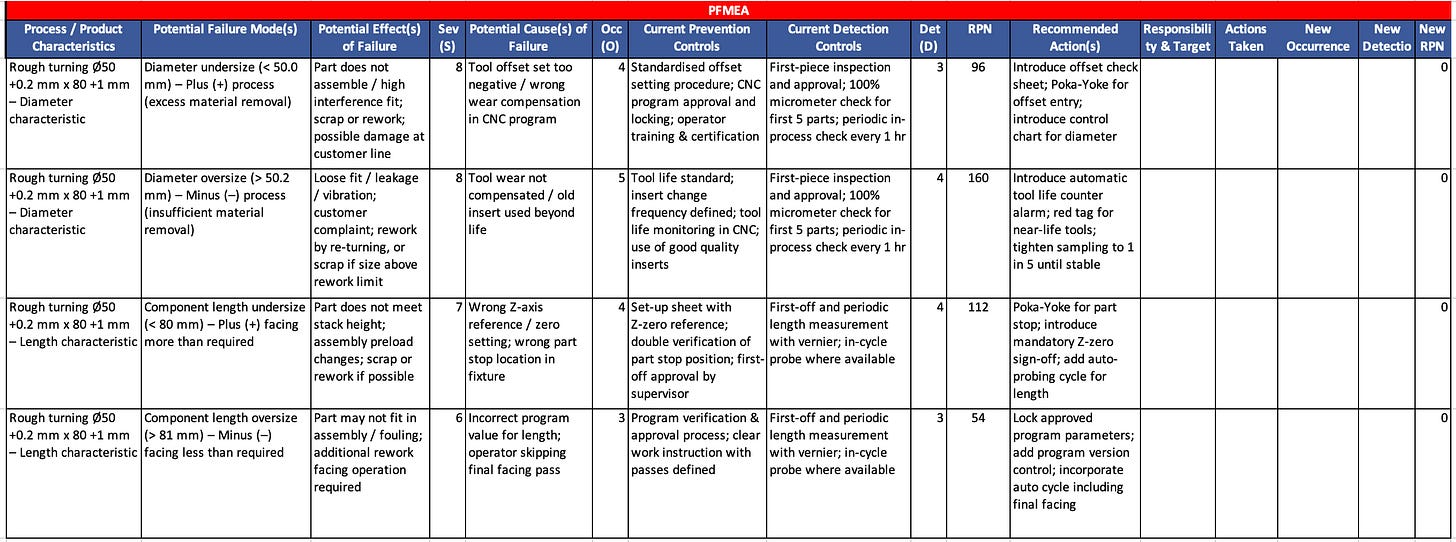

How the process is controlled and the frequency of controls (be it visual inspection or measurement) depend on the failure mode and the severity and occurrence scores of the FMEA, coupled with capability studies. Therefore, it is important to have a good FMEA before you make a Control Plan. So, visit the previous blog and complete your FMEA.

Now let us prepare a Control Plan, taking a reference from the previous article.

If you are interested in AI and want to learn more, check out my previous articles.

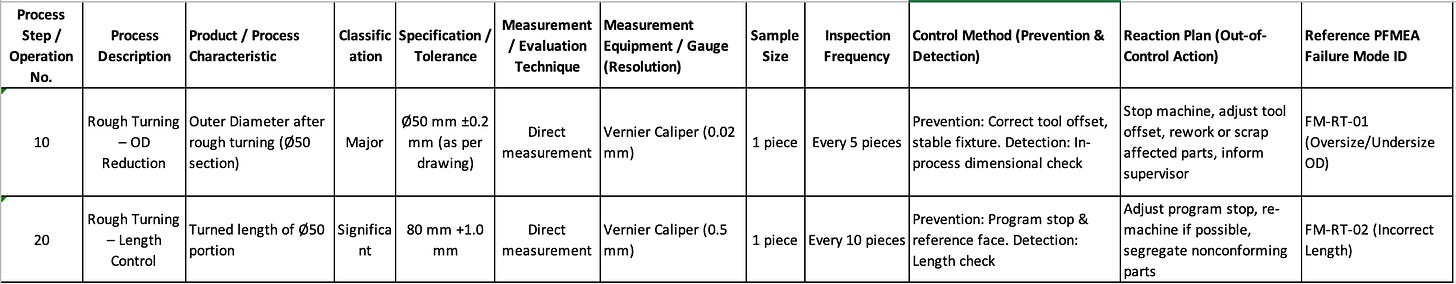

Case Study: Creating a Control Plan for a Rough Turning Operation

Creating a Control Plan for a rough turning of a steel rod.

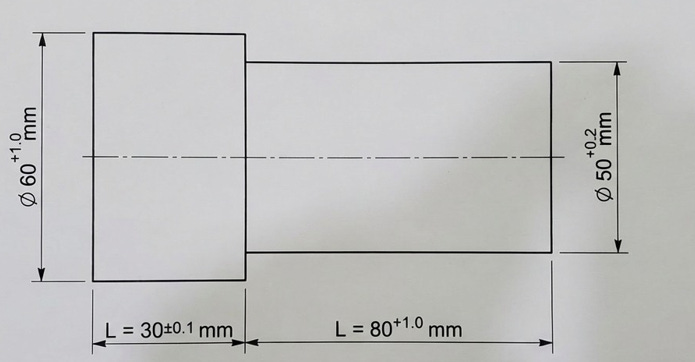

Process: Carry out rough turning to achieve Ø50 mm for a length of 80 mm from a blank of Ø60 of length 111 +1 mm.

Please note as Automotive Industry Action Group (AIAG) is the most used template for control plan I will be using the same in my prompt.

Using Prompts

Step 1: Log in to ChatGPT.com

Since it is freely available, I’m using it for this demonstration. The same workflow can be done using any advanced GPT model.

Step 2: Upload PFMEA and Drawing

PFMEA created using the previous blog

Step 3: Upload your drawing (optional but suggested)

Engineering Drawing Uploaded

Important Note on Prompt Writing

A well-structured and detailed prompt consistently leads to high-quality results.

The quality of the output is directly proportional to the quality of the prompt you write.

While it is possible to simply upload the drawing and the PFMEA and ask the AI to generate a Control Plan, the outcome may vary. You might get a good Control Plan occasionally, but such results are often inconsistent—especially when you are creating multiple documents across different parts or processes.

To ensure accuracy, repeatability, and professional consistency, it is strongly recommended to use a detailed and technically structured prompt. A precise prompt guides the AI to align with engineering intent, standards (such as AIAG Control Plan methodology), and PFMEA logic, resulting in reliable and standardized outputs every time.

Input prompt:

Prompt: Create a Manufacturing Control Plan (Rough Turning Operation)

Using the attached engineering drawing and the referenced Process FMEA (PFMEA), create a Process Control Plan for a rough turning operation with the following details:

Process Description

· Operation: Rough Turning

· Objective: Achieve Ø50 mm ± drawing tolerance over a length of 80 mm

· Raw Material: Cylindrical blank Ø60 mm × 111 mm (+1 mm allowance)

· Machine Type: CNC / Conventional Lathe (as applicable)

Control Plan Requirements

Prepare the Control Plan strictly aligned with AIAG Control Plan methodology

FMEA Alignment Logic (Mandatory)

· Refer to PFMEA failure modes

· Align control methods and inspection frequency based on Risk Priority derived from Severity (S), Occurrence (O), and Detection (D) ratings.

· Clearly demonstrate traceability between PFMEA controls and Control Plan controls.

Output Requirements

· Deliver the Control Plan in a professionally formatted, downloadable Excel (.xlsx) file

· Use clear headers, consistent units, and manufacturing-standard terminology

· Ensure the Control Plan is suitable for shop-floor execution and customer audit review

Assumptions (if any)

· Clearly list reasonable assumptions if drawing or PFMEA information is incomplete

· Do not invent tolerances—use drawing-based or clearly stated assumptions only

Important Notes:

1. Be consistent in using the control mechanism instruments from the FMEA and the control plan.

2. Do not assume any additional dimensions and parameters unless otherwise specified in the FMEA and drawing attached.

Option in the prompt:

· Machine & Operator Details

· Machine: CNC Machine

· Type: Semi-automatic

· Operator: Skilled operatorOutput

Your Control Plan will be ready in just a few minutes

With these instructions, ChatGPT can generate a complete, professional Control Plan aligned with AIAG Standard .

What’s Coming Next? (Don’t Miss Out)

In the next part of this series, we’ll complete the Golden Thread by showing how to create a Shop-floor Ready SOP using AI.

We’ll cover:

How to convert your Control Plan into a practical SOP

AI prompts to generate operator-friendly, audit-ready SOPs

Ensuring traceability across PFMEA → Control Plan → SOP

Common mistakes manufacturers make while documenting SOPs — and how AI helps avoid them

If you’re serious about building consistent, compliant, and scalable manufacturing documentation, you won’t want to miss what’s coming next.

Fantastic walkthrough of AI-assisted Control Plan generation. The emphasis on prompt quality over just uploading files is key; I've seen too many teams struggle with inconsistent outputs becuase they skip the structured prompt step. The PFMEA-to-Control Plan traceability framing makes audit prep way smoother, and linking failure modes directly to control freqency is where the real value hides. Curious how this scales when dealing with high-mix low-volume manufacturing where process parameters shift often.