AI in Manufacturing Part (1) : Creating FMEA with AI

Discover how AI is revolutionising manufacturing quality control in 2026. This guide, co-authored with Lean Six Sigma expert Srinivas T V, shows you how to generate accurate Process FMEAs in minutes u

While 2025 witnessed a surge in AI adoption across service industries, I believe 2026 is poised to be the year for AI in other industries (non-tech), and one among them is manufacturing. From automotive and aerospace to food processing, any manufacturing setup will see a surge in the use of AI tools.

This article is co-authored with one of my earliest bosses at Bosch, Srinivas T V — B.E., M.Tech, Master Black Belt, and a serial entrepreneur/founder of Lean6Sigmapro.com, Study100on100.com, and Skoolz.in. Srini is exceptional at building process FMEAs and Six Sigma systems, and we worked together on the Starter Assembly line for the Tata Nano. Today, he is recognised as a pioneer in combining AI with Lean Six Sigma, helping industries transform continuous improvement. His consultancy has saved clients millions, and he now builds AI-driven manufacturing problem-solving tools that enable faster, smarter, data-backed decisions.

In this blog series, we will be sharing how Process and Quality Engineers in manufacturing can make use of AI tools to increase their accuracy and efficiency and get the “Golden Thread” in shape. Let us start with the most basic tool: FMEA.

What follows is Srini’s perspective on why FMEA remains the backbone of manufacturing excellence—and how AI now makes it dramatically faster, easier, and more accurate to execute.

No Time to Read? Here’s the Scoop

AI Is Finally Hitting the Shopfloor : From automotive to aerospace, every line is about to get smarter.

PFMEA in Minutes, Not Weeks :With ChatGPT or a Custom GPT, you can generate a 90%-accurate PFMEA fast—no marathon meetings, no chaos. Just upload your template, add a drawing, and run the prompt.

A Clear, Repeatable Method : This guide breaks down the exact workflow we use to automate PFMEAs using your own formats and standards. No fluff—just a system that works.

End Result

A clean, ready-to-edit PFMEA that normally takes weeks—now done in minutes.

Failure Modes and Effects Analysis (FMEA): The Foundation of Manufacturing Excellence

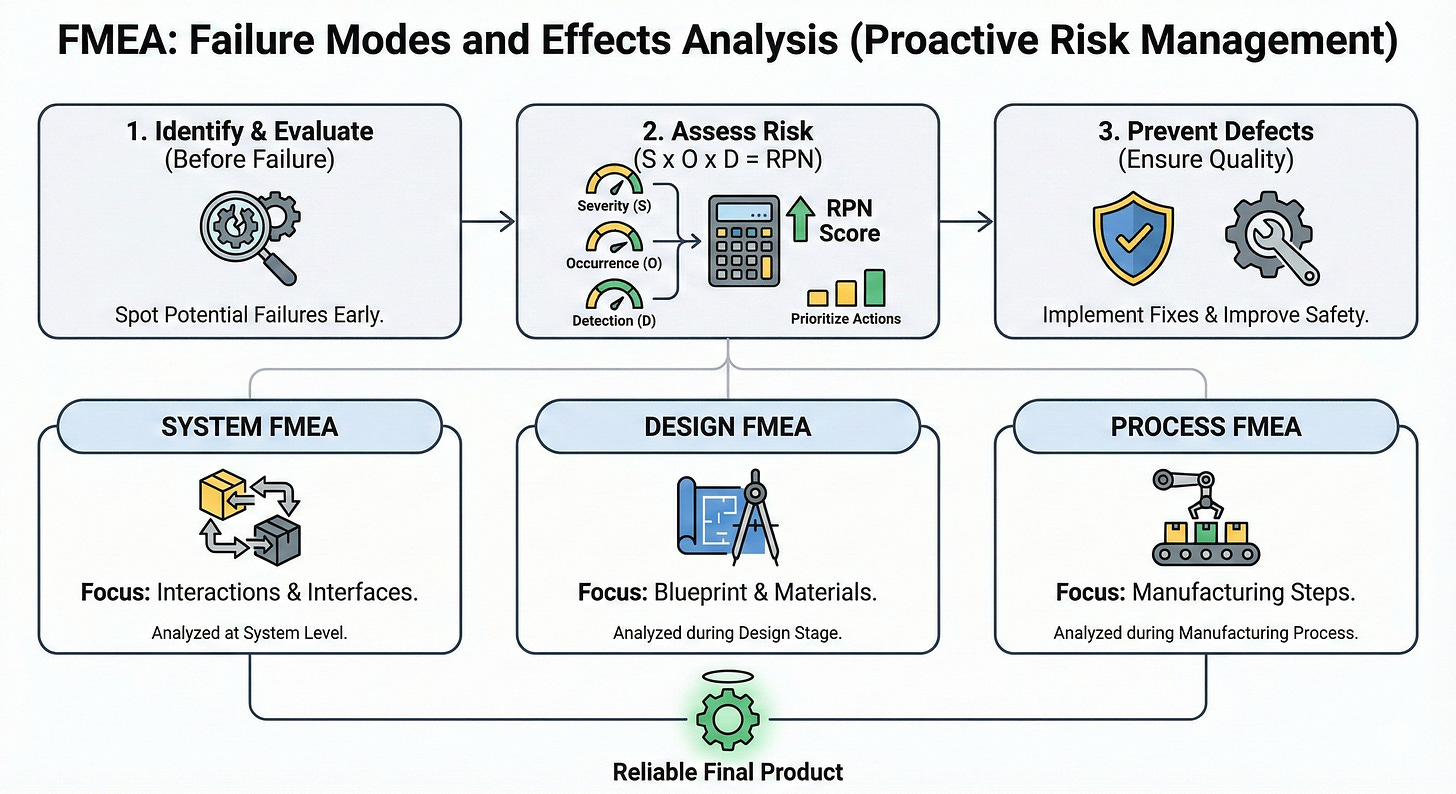

Failure Modes and Effects Analysis (FMEA) is a systematic, proactive method used to identify and evaluate potential failures in a system, product, or process before they occur. It helps organizations assess risks, prioritize actions, and prevent defects, ensuring quality, reliability, and safety.

There are 3 types of FMEA:

System FMEA: Failures are analyzed at the system level.

Design FMEA: Failures are analyzed during the design stage.

Process FMEA: Failures are analyzed during the manufacturing process.

FMEA is a powerful tool used across industries. When applied effectively, it significantly enhances product quality and reliability.

The usage dates back to the 1950s in US aerospace and military. Then NASA started using it in the 1960s, the 1970s saw deeper usage in the automotive industry, and finally the 2000s is when other manufacturing companies like pharma and medical equipment started using the same. Today, other industries like services have embraced concepts of FMEA in a slightly modified way.

Ask any seasoned quality or process professional about the foundations of manufacturing excellence, and FMEA (Failure Mode and Effects Analysis) invariably tops the list.

Check out my previous articles:

A Five-Day Training, A Decade of FMEAs, and a Future Powered by AI

I’ll never forget my first professional training at Bosch. Fresh out of college, I found myself in an intensive five-day FMEA training program. I must have created, moderated, and mentored 50+ FMEAs so far.

FMEA methodology has been the unsung hero behind the exceptional quality performance in space, aerospace, and automotive industries.

Yet here’s the paradox: despite knowing FMEA’s advantages and understanding the methodology inside-out, many companies—even large multinational corporations—struggle to execute it properly. When FMEA is conducted, it often lacks the necessary detail. The usual suspects? Lack of time from cross-functional teams and insufficient discipline among engineers.

How to create FMEA with AI: A Step-by-Step Guide for Manufacturing Teams

But what if I told you that the same comprehensive FMEA could be prepared in just a few months for an entire process? We’ve done exactly that.

Using AI tools, we’ve created detailed FMEAs for multiple processes in minutes. The accuracy? 90%+ -- Much better than many FMEAs I have reviewed and easily comparable to what traditionally took months of team meetings and revisions.

Now, let me show you the step-by-step method to create a PFMEA (the most widely used FMEA).

As FMEA is primarily used in manufacturing more than any other industry, and the positive impact of FMEA is significant in manufacturing, let me explain how FMEA can be created in minutes using AI. Other industry professionals can try the FMEA GPT in Option 2.

Case Study: Creating a PFMEA for a Rough Turning Operation

Case Study: Creating a PFMEA for a rough turning of a steel rod.

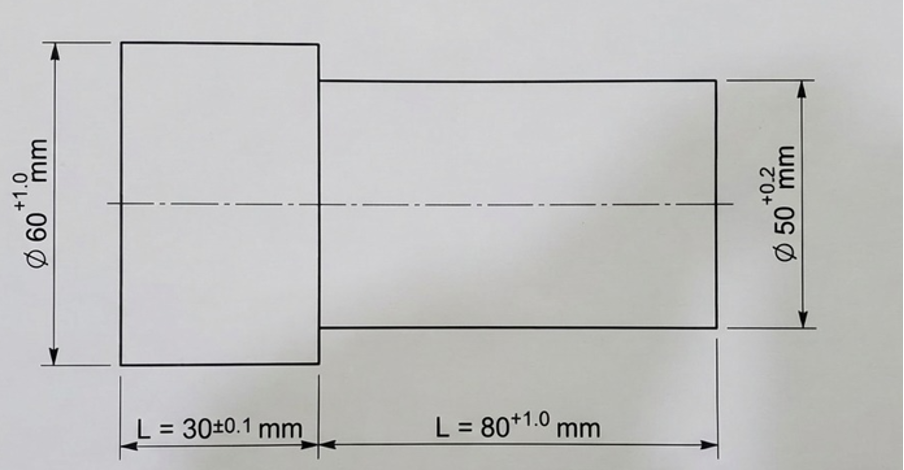

Process: Carry out rough turning to achieve Ø50 mm for a length of 80 mm from a blank of Ø60 of length 111 +1 mm.

Option A – Using Prompts

Step 1: Log in to ChatGPT.com

Since it is freely available, I’m using it for this demonstration. The same workflow can be done using any advanced GPT model.

Step 2: Upload your PFMEA template

Preferably upload it in Excel format.

If you don’t have one, you can use the sample template as an image, but Excel is always preferred for accurate formatting and ease of editing.

Step 3: Upload your drawing (optional but suggested)

You must attach the final drawing. You can also draw it with your hand and give it to AI Model. AI Models are becoming smarter and they can understand if the drawings are reasonably good enough.

Step 4: Write your prompt

Example prompt:

“Use the attached FMEA template and create a PFMEA for the rough turning operation to achieve a 50 mm diameter for an 80 mm length as per the drawing.” Provide the PFMEA in a downloadable Excel format.

This prompt alone is enough to generate a usable PFMEA.

However, you can add more detailed instructions for increased accuracy and alignment with your internal standards.

Additional Instructions You Can Include (Recommended)

Failure Mode Identification

Use the Plus / Minus / Zero approach:

Plus (+): Doing the process more than required

Minus (–): Doing the process less than required

Zero (0): Not doing the process at all or skipping it

Other Important Notes

Ensure all process steps are included.

Consider only realistic and possible failures—no imaginary cases.

Machine & Operator Details

Machine: CNC Machine

Type: Semi-automatic

Operator: Skilled operator

SOD Ratings: Use the generic Automotive Industry S–O–D rating standards

Output ✔ Your PFMEA will be ready in just a few minutes

With these instructions, ChatGPT can generate a complete, professional PFMEA aligned with automotive-quality standards.

Subscribe now to get these guides delivered straight to your inbox. If you are a Quality Engineer or Manufacturing Lead, you cannot afford to miss the “Control Plan” edition

Option B

You can also create PFMEA by answering the questions using my Custom GPT: https://chatgpt.com/g/g-CLtbsqm4y-fmea

Good thing that it gets added to your GPTs and can create PFMEA anytime you need. I hope you were able to create PFMEA using the steps below. Please let me know if this is useful for you.

What’s Coming Next? (Don’t Miss Out)

This is just the beginning of our deep dive into AI for Manufacturing.

In the coming weeks, Srini and I will be releasing Part 2 and Part 3 of this series, where we’ll share deeper insights on how AI is reshaping other key quality tools:

AI-Driven Control Plans: How to link your FMEA directly to control measures instantly.

AI-Driven SOPs: Generating work instructions that operators will actually read.

Excellent guide! I followed Option 2 to create a PFMEA for a new activity we are planning to implement, and the step-by-step approach made the process fast and straightforward. It highlighted key points with minimal effort required for fine-tuning. I found this extremely practical and useful, and I’m looking forward to sharing it with my circle—it’s truly awesome!

Brilliant walkthrough of the FMEA automation process. The Plus/Minus/Zero framwork for failure mode identification is probaly the most underrated part here becuase it forces structured thinking even when using generative models. I dunno if the 90% accuracy claim holds across all machining operations, but the template-based appraoch definitely reduces that initial blank-page friction most quality teams face.