AI Application in Real Industry : Maritime Shipping Industry

How AI in maritime and bulk shipping prevents collisions, optimizes voyages, and predicts engine failures—real CO2 cuts and six‑figure savings per ship.

Over the last few articles, we’ve explored how AI is reshaping creativity, workflows, and even decision-making. But the real test of this technology is when it leaves our laptops and meets the real world — the industries that move, build, and power our planet.

That’s why, for this story, I wanted to dive into one of the most unexpected frontiers of AI: bulk shipping — a world of giant vessels, unpredictable weather, and billion-dollar cargoes.

To understand how AI fits into that environment, I reached out to Siddharth Arya, a dry-bulk shipbroker turned AI builder who has spent over two decades navigating the global shipping trade.

As the head of Aryacorp, a 40-year-old boutique brokerage renowned for its sharp market intelligence, Siddharth brings a rare insider’s view — blending deep industry experience with cutting-edge AI thinking. He’s not a technologist trying to disrupt shipping — he’s a shipping insider using AI to modernize it from within. His work spans maritime automation, executive assistance, health, and finance, all guided by one belief: technology should feel natural, helpful, and human.

In this piece, Siddharth takes us behind the scenes to show how AI is quietly revolutionizing maritime operations — from preventing collisions to predicting maintenance — and what it means for anyone learning or building in AI today.

You can follow Siddharth’s work on LinkedIn or reach out at siddhartharya@gmail.com

No Time to Read? Here’s the Scoop — Maritime AI Highlights

Maritime computer vision on ships reducing collision incidents by 54%

AI voyage optimization saving 1.8 million tonnes of CO2 in 2024

Predictive maintenance for marine engines cutting engine failures by 20-30%

1,200+ ships currently using these systems (not pilots, actual production)

Real impact: $100,000 saved per ship annually

Siddharth’s Product : Building two AI solutions for dry bulk that tackle market intelligence and contract generation

If you are getting started, then start with these article and subscribe to be updated:

Siddharth Arya writes:

Here’s something that might surprise you: while you’re playing with ChatGPT and generating images with Midjourney, some of the coolest AI applications are happening on massive cargo ships in the middle of the ocean.

I know. Ships? Really?

Trust me on this. I’ve spent 20 years in bulk shipping, and now I work with AI. Watching these two worlds collide has been fascinating, and it taught me things about real-world AI that no online course ever did.

Let me show you what I mean.

What are the challenges faced in Maritime Shipping Industry

Picture this: You’re on a ship the size of three football fields, carrying 180,000 tonnes of iron ore from Australia to China. It’s 2 AM, foggy, and your radar shows 30 other vessels nearby. You’re passing through the Strait of Malacca, one of the world’s busiest shipping lanes.

Which dots on your radar are fishing boats?

Which are massive tankers?

Is that small target moving toward you or away?

This is where people make mistakes. And mistakes cost lives, millions of dollars, and can cause environmental disasters.

Enter AI.

Use Case 1: Maritime Computer Vision That Sees Through Fog

A company called Orca AI built a system that uses cameras and computer vision to create a 360-degree view around the ship. It works in fog, at night, in heavy rain. Conditions where even experienced sailors struggle.

Here’s what makes it cool: They trained their AI on over 100 million nautical miles of real ocean footage. Actual ships, in actual weather, with actual obstacles.

The results? Close-call incidents dropped 54%. Ships save $100,000 per year in fuel because you don’t need dramatic evasive maneuvers anymore. Currently protecting 1,200 ships worldwide.

This isn’t a pilot program. This is production AI preventing collisions right now, somewhere in the Pacific Ocean.

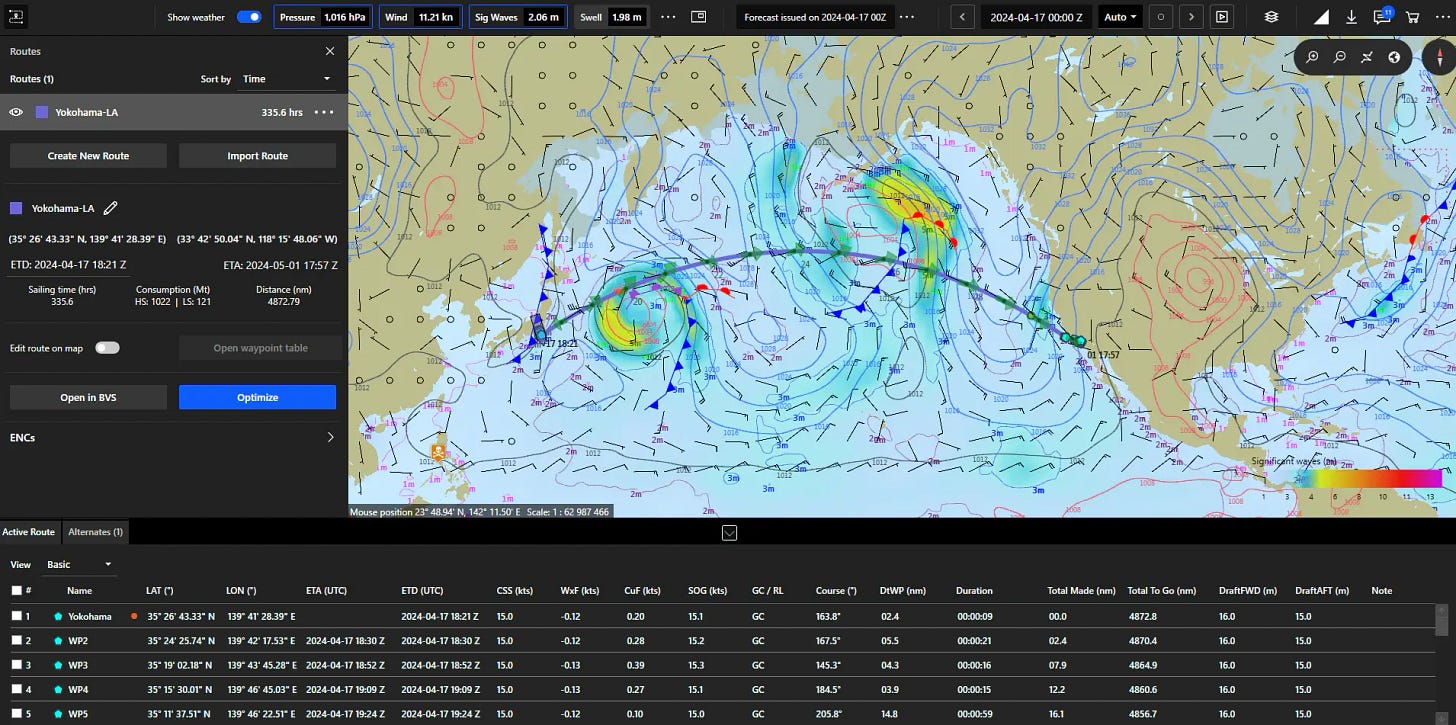

Use Case 2: AI Voyage Optimization and The Route Optimization Problem

Imagine planning a 35-day voyage from Texas to Japan. You need to consider weather (typhoons, ocean currents, waves), fuel costs ($24,000 per day), port congestion at your destination, speed versus arrival deadlines, and environmental regulations.

Traditional approach? An experienced captain, weather reports, and intuition.

AI approach? StormGeo’s system analyzes eight different route options in seconds, considering real-time weather forecasts, ocean currents, fuel consumption, and even port congestion data.

Real example: A ship faces a developing cyclone. The AI suggests a slightly longer southern route at reduced speed instead of rushing north at high speed. Result: Ship arrives on time, burns 8% less fuel, everyone safe.

In 2024 alone, StormGeo optimized 75,000 voyages and saved 1.8 million tonnes of CO₂ emissions.

Want to know in detail, checkout this video:

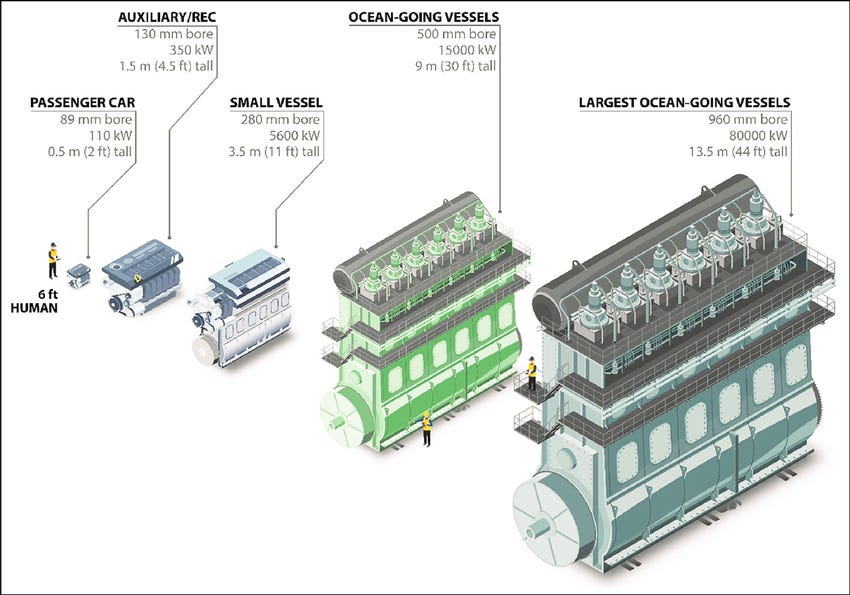

Use Case 3: Predictive Maintenance — Predicting Engine Failures Before They Happen

Ship engines are massive. Like, the size of a small house. If one breaks down at sea, it costs anywhere from $500,000 to $1 million in repairs, towing, and lost time.

Wärtsilä (a major engine manufacturer) put sensors all over ship engines. Temperature, vibration, pressure, oil quality. Everything gets monitored continuously.

Machine learning models analyze this data and predict: “Hey, this bearing is showing unusual vibration patterns. It’ll probably fail in 10 days. Schedule maintenance at your next port.”

Instead of emergency repairs at sea, you handle it during a planned port stop. Downtime drops 20-30%. Costs plummet.

If you are enjoying reading such information, do subscribe

What I’m Building: Bringing AI to Dry Bulk Operations

All of this got me thinking: where are the real gaps in dry bulk shipping that AI can actually solve?

If you’re not familiar, “dry bulk” refers to cargo like coal, iron ore, grains, or cement — goods shipped unpackaged in large quantities on specialized vessels called bulk carriers. Managing these shipments involves complex coordination across ports, weather routes, and contracts.

I’m quietly building two solutions that came directly from pain points I’ve felt working in this industry.

Maritime Market Intelligence

The first tackles market intelligence. Right now, if you’re a freight trader deciding whether to fix a Panamax today or wait, you’re manually checking: Baltic Index movements, yesterday’s fixture reports, port congestion data, commodity prices, fleet positioning, and broker sentiment across emails, PDFs, and websites.

I’m building an AI agent that ingests all these sources, understands bulk shipping context (not just generic data patterns), and outputs clear recommendations: ‘Fix now at $12,000/day. Model predicts 75% probability rates drop $800 in 3 days based on: increasing ballast tonnage in Atlantic + softening iron ore prices + recent Valemax fixtures at discount.’

It’s using LLMs for understanding unstructured text (broker emails, news), multimodal processing for handling tables/charts/PDFs, and agent-based reasoning to connect the dots across different signal types.”

Quick Glossary for understanding

Shipping Terms:

Panamax: A medium-sized cargo ship (around 70,000 tons) designed to fit through the Panama Canal

Fix: Lock in a ship rental rate for transporting cargo

Baltic Index: The stock market of shipping - tracks global ship rental prices daily

Fixture reports: Records of recently agreed ship rental deals

Ballast tonnage: Empty ships looking for cargo (high numbers = more competition = lower prices)

Valemax: World’s largest bulk carrier ships, used mainly for iron ore

Market Factors:

Port congestion: Traffic jams at ports that affect ship availability

Fleet positioning: Where ships are currently located globally

Iron ore prices: Key cargo for bulk ships; when prices fall, shipping demand drops

AI Technology :

LLMs (Large Language Models): AI that reads and understands text like ChatGPT

Multimodal processing: AI that can read different formats (text, charts, images, PDFs)

Agent-based reasoning: AI that connects multiple pieces of information to make decisions

Freight Contract Creation

The second solves freight contract creation. Anyone who’s worked with freight contracts knows the pain: manual clause selection, legal ambiguity, commercial misalignment. I’m using structured data extraction, legal-trained LLMs, and rule-based validation to turn basic fixture terms into actual freight contracts with the right riders and safeguards. The tech stack blends large language models, retrieval-augmented generation, automated document parsing, and workflow agents that self-check for accuracy.

Why am I building these? Because I’ve lived the day-to-day friction. My domain knowledge showed me where the real problems are, and my AI exposure showed me how to solve them without adding complexity or “tech for the sake of tech.”

I’ve validated both through private conversations with market players, testing prototypes on real fixture deals and freight contracts. The feedback has been consistent: if AI can reduce ambiguity, protect commercial interests, and save time without changing how we work, it gets adopted.

That’s the sweet spot. Not replacing people. Not forcing new workflows. Just making the existing job less painful and more accurate.

Career Lessons from Both Worlds - Shipping + AI

Here’s what surprised me most as someone who bridges shipping and AI:

The biggest opportunities aren’t consumer apps. They’re in industries you never think about. Shipping, manufacturing, agriculture, construction. Real problems, real budgets, and companies desperate for solutions.

Domain expertise plus AI skills is rare and valuable. Pure AI skills? Common. Deep industry knowledge plus AI? That’s the combination companies actually pay for.

Data quality beats fancy algorithms. I’ve seen companies fail at AI not because their models were bad, but because their data was a mess. Clean data, even with simple models, wins every time.

Why This Matters If You’re Learning AI

When I talk to people learning AI, they often think it’s all chatbots and image generation.

But right now, AI is preventing ship collisions, saving millions in fuel, predicting equipment failures, and cutting carbon emissions.

And shipping is just one industry. There’s similar work in factories, farms, power grids, hospitals, and warehouses. Every traditional industry needs people who can bridge domain knowledge and AI implementation.

How to Get There

If this intrigues you, here’s what I’d suggest.

Pick an industry and actually learn it. Not surface-level, but deep enough to understand the daily problems.

Read their publications.

Talk to people who work there.

Build something that solves a real problem. Optimize warehouse routes. Forecast agricultural yields. Something that matters to an actual business.

The Bottom Line

I spent 20 years in shipping before learning AI. Now I help shipping companies figure out where AI actually makes sense, and I’m building solutions for the gaps I know exist.

What I’ve learned: The sexiest AI work isn’t always the most visible.

Nobody writes viral tweets about shipping AI. But the companies deploying it are saving millions, preventing accidents, and cutting emissions at massive scale.

The future of AI isn’t just in consumer apps. It’s in cargo ships, factories, farms, and power plants. It’s in industries needing smart people who understand both technology and operations.